Minden – MINDA is awarded the TOP 100 seal for 2026. This makes MINDA one of Germany's most innovative medium-sized companies. The award ceremony will take place during the German SME Summit in Heidelberg on June 26. Former German Federal President and Lower Saxony Federal Prime Minister Christian Wulff, who mentors the TOP 100 innovation competition, will also attend.

More than 100 evaluation criteria of the scientific selection process are evaluated by Professor Nikolaus Franke and his team on the basis of a questionnaire: "At TOP 100, we analyze thoroughly and comprehensively how innovation-oriented the applicants are. And those who are outstanding are confirmed with the TOP 100 seal," says Professor Nikolaus Franke.

"We are proud to win this prize. It is the perfect proof of how innovative we are and that all the sweat, passion, and commitment we have put into every single project over the years has paid off," says Robert Falch, managing partner of MINDA Industrieanlagen GmbH.

Specialized in mechanical and plant engineering, MINDA develops and manufactures solutions for customized and intelligent material flow in a wide range of sustainable industries. Our products from intralogistics, plant engineering, and conveyor technology are used, for example, in the corrugated board industry, solid wood industry, automotive industry, and panels industry.

Dr. Kai Ventz, head of MINDA's research and development department, knows what matters in every single project: “Innovative strength is in our MINDA DNA, because that is exactly what matters in customer-specific projects. We don't offer off-the-shelf solutions – we make the impossible possible for our customers where others don't even dare to try!”

In order to continuously advance corporate innovation, all employees at MINDA are involved. The "Ideenschmiede" (think tank) is a central platform for employee suggestions that specifically turns employee knowledge into measurable improvements.

In addition, MINDA's innovative strength is evident in the implementation of diverse projects:

"In the field of high-bay warehouses, we work with established partners, but when it comes to special requirements such as low construction heights, our innovative strength is needed to create the best possible solution for the customer," explains Robert Falch. For example, a storage and retrieval machine called the Compact Crane was developed specifically for the company's in-house storage solutions. The Compact Crane is used, for example, in the corrugated board and solid wood industries.

Special expertise is also required in the field of press technology for the solid wood industry: in order to be able to respond to customer-specific and market requirements, innovative ideas are needed, particularly in the fields of hydraulics and press technology, process and material knowledge, automation, and quality assurance. In this area, for example, MINDA has developed a four- and even five-chamber rotor press in which several glulam beams can be pressed simultaneously.

In order to promote innovation in the long term, MINDA is also collaborating with the University of Hanover on a basic research project on the "elephant foot."

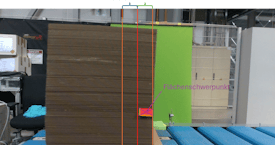

In plants for the manufacture of corrugated boards, corrugated board sheets are transported in stacks. Ideally, the stack maintains a rectangular shape throughout the entire transport. Due to the configuration of the system, which has several transfer points and discharge devices, it is assumed that impulses are transferred to the corrugated board stack, causing the individual sheets to align themselves in a characteristic way: They form "lagging" lower sheets. This effect is known as sheet walk effect or –“elephant foot”. In collaboration with university research institutions, such as the Institute for Transport and Automation Technology at Leibniz University Hannover, possible influencing factors are being characterized and a simulation model is developed in order to make reliable predictions and take appropriate measures.

MINDA is also focusing on the use of artificial intelligence as a driver of innovation. Examples include AI-supported detection of stacking strips in solid wood plants and the use of transfer cars in the corrugated board industry, where transport routes are optimized using artificial intelligence. In addition, MINDA uses an AI-based warning system in this area that reliably detects people in the vicinity of transport routes.

And that is just a glimpse into our broad innovation portfolio. We look forward to playing an active role in shaping the future of intelligent material flow with our ideas!

About the TOP 100 competition

Since 1993, compamedia has awarded the TOP 100 seal to medium-sized companies for exceptional innovative strength and above-average innovation success. Prof. Dr. Nikolaus Franke has been the scientific director since 2002. Franke is the founder and director of the Institute for Entrepreneurship and Innovation at the Vienna University of Economics and Business. With 27 research awards and over 200 publications, he is one of the leading innovation researchers internationally. The mentor of TOP 100 is former German Federal President and Federal Prime Minister Christian Wulff. Project partners are the Fraunhofer Society for the Promotion of Applied Research and the SME association BVMW. The magazine "manager magazin" accompanies the company comparison as a media partner, and the magazine "ZEIT für Unternehmer" as a cooperation partner. More information and registration at www.top100.de.